The sight is a precision device manufactured with close tolerances to ensure accuracy and repeatability.

Outlined below is the recommended cleaning and maintenance procedure to ensure that the sight performs to it’s full potential.

Cleaning

- Do not clean the sight with any solvents.

- The best method of removing dust and debris is to dab the exposed spindles and guide pins with a piece of Blu Tack.

- The Blu Tack can be cleaned after use by rolling it between the palms of your hands.

Lubrication

- Only lubricate the sight with the recommended lubricant that can be procured from your rifle association store.

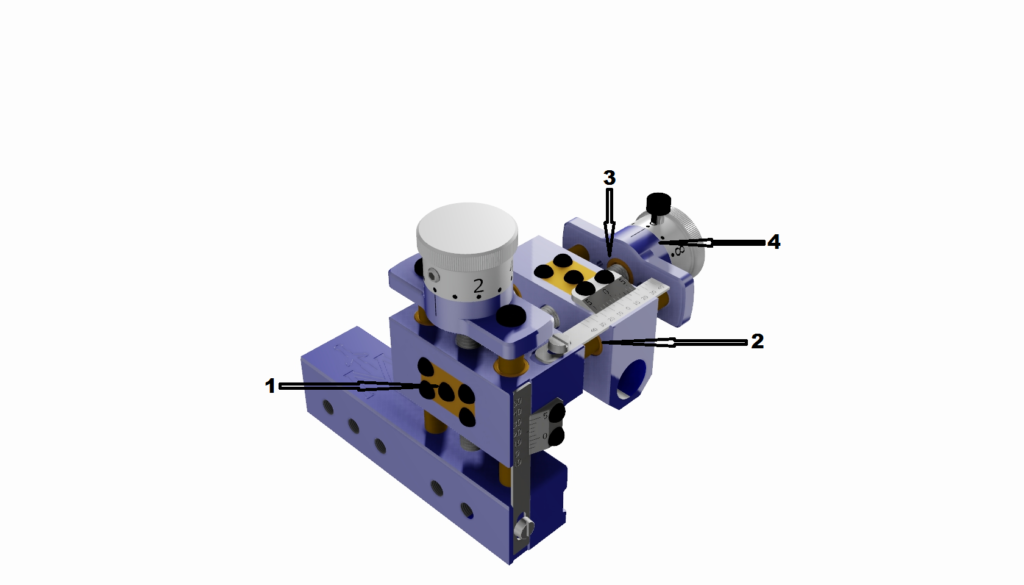

- Remove the dome head cap screw in the middle of the brass plate that covers the backlash mechanism. (1)

- Only remove the screw in the middle of the brass plate as the other screws retain the mechanism with its springs.

- Be careful when removing and installing the dome head cap screw as the thread will strip if too much force is applied.

- Apply a few drops of lubricant to the inside of the backlash mechanism through the tapped hole.

- Apply a drop of lubricant to either side of the bushes that ride on the guide pins. (2)

- Apply a drop of lubricant to the thrust bushes. (3)

- Apply a drop of lubricant to the interface between the knobs and sight. (4)

- Wind the windage and elevation carriers to just short of their limits on either side to ensure that the spindles, guide bushes and rods are fully lubricated.

- Do not wind the elevation or windage carrier hard up against any surface.

- After lubrication wipe off any excess oil with a lint free cloth.

- If you cannot procure the lubricant from your rifle association store then only use pharmaceutical grade white oil.